補上臨門一腳的好聲音

﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏

廠機零件通常都是採用快速、制式化的大量製作,品質只能稱得上是堪用,若是高級機種要用的話,則頂多是另購高規一點的零件來使用。但對於喜愛DIY的玩家來說,已將自家系統調整到一定程度後,若沒有換機的打算、又想要讓系統更進一步的提升,改機就是其中一個方法。其中,進入器材的第一個元件「機尾座」,就絕不能忽視它,它可是關乎「電源」進入器材電路的第一步。

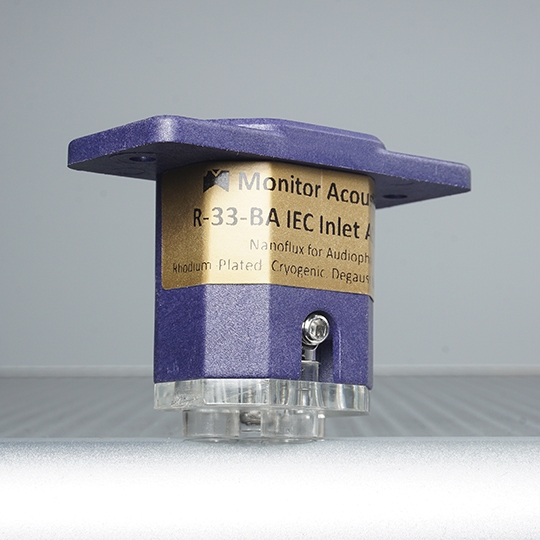

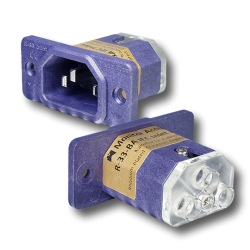

MA靜神一開始為自家產品設計了「R-11」機尾座,給旗下的電源清淨處理器使用,對於機尾座的眉眉角角都研究的相當透徹,而且常有客人私下央求要我們賣幾個給他,因此萌發了我們再開發一款專門給玩家DIY用的機尾座,才會誕生這款「R-33」機尾座。這款機尾座以R-11為基礎再升級,在外殼絕緣材中加入了耐燃級尼龍纖維(nylon)及奈米陶瓷粉、碳粉等等……多種微量元素,能在無形中釋放微量負離子與遠紅外線,在複雜的電磁場中,能夠隔絕干擾,讓電源穩定順暢地通過,確保電能無染的傳輸,保持低底噪、高速傳輸的優異性能;此外,導電材選用了鍗銅合金,並利用精密CNC、將原本直徑達6mm的鍗銅合金,削切至符合IEC規定的2mm端子厚度,經過慢速奈米級研磨後,再鍍上電子級貴金屬「銠」,最後佐以-196°C超冷處理,讓金屬原子更加緊密排列,並消除先前工序上的金屬應力,展現最直接的電能傳導能力。獨特、優越、高性能的「R-33」在入線端,將最大入線容許值設定在4mm,提供充足、寬頻的電能通道,滿足大食量需求的設備,並以不感磁的不鏽鋼螺絲固定導線。MA靜神專注細節,在專業、嚴苛的音響實驗室內,反覆聆聽比較導材、電鍍、介電材配方,最終才把最到最好產品呈現給玩家,讓用家一聽上癮、用上了就拔不下來。

﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏

FEATURES 特點:

導電材選用鍗銅合金( Tellurium Copper),利用精密CNC削切至符合IEC規定的2mm厚度,經過慢速奈米級研磨再鍍上電子級貴金屬「銠」,最後佐以-196°C超冷處理。

介電絕緣材使用耐燃級尼龍纖維(nylon)及奈米陶瓷粉、碳粉等等……多種微量元素,能在無形中釋放微量負離子與遠紅外線,

最大入線容許值:4mm

尺寸:約50×23×39mm (W×H×D)

重量:約26g

﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏

R-33 IEC Inlet (Three-Prong Version)

The Final Touch That Makes All the Difference

﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏﹏

Most stock components rely on fast, standardized mass production—functional, but far from ideal. Even in high-end gear, power inlets are often just adequate at best. But for serious DIY audiophiles who've already fine-tuned their systems to a high level and are looking for that last upgrade without replacing entire components, the power inlet—where electricity first enters your device—is absolutely critical.

That’s why we created the R-33 IEC inlet. Originally designed as an upgraded version of our internal R-11 model (used in our own power conditioners), it was born from demand—many customers kept asking to buy our inlets separately. So we took the proven performance of the R-11 and elevated it even further, with materials and construction specifically engineered for high-fidelity performance.

The R-33 features an advanced insulating body made from flame-retardant nylon reinforced with nano-ceramic powder, carbon particles, and trace elements. These materials subtly emit negative ions and far-infrared energy to help stabilize electromagnetic fields, improving power flow, minimizing interference, and preserving clean signal transmission for lower noise and faster transient response.

For conductivity, we selected tellurium copper, CNC-machined from a 6mm rod down to a precise 2mm terminal to meet IEC standards. After ultra-fine slow-speed polishing, the contact surfaces are plated with electronics-grade rhodium for superior signal clarity, then cryogenically treated at -196°C to relieve stress and realign metal grain structure for optimal conductivity.

The R-33 accepts power cables up to 4mm², making it ideal for high-current setups, and uses non-magnetic stainless steel screws to secure wiring. Every detail has been tested and tuned through extensive A/B listening sessions in our reference labs, comparing conductor types, platings, and dielectric formulas until we found the perfect recipe. One listen, and you won’t want to go back.

FEATURES

- Conductive parts made from precision CNC-machined Tellurium Copper

- Ultra-fine slow polishing followed by rhodium plating and -196°C cryogenic treatment

- Dielectric housing blends flame-retardant nylon with nano-ceramic and carbon additives, releasing negative ions and far-infrared energy

- Large wire entry accommodates cables up to 4mm²

- Non-magnetic stainless steel screws for wire termination

- Dimensions: approx. 50 × 23 × 39mm (W × H × D)

- Weight: approx. 26g